型號:JH錦工-50U、JH錦工-65U、JH錦工-80U、JH錦工-100U、JH錦工-125U、JH錦工-150U、JH錦工-200U、JH錦工-250U、JH錦工-300U、JH錦工-350U

壓力:29.4kpa~78.4kpa風量:1.52~58.02 m3/min

電機功率:1.5KW~110kw

密集型羅茨鼓風機,它集羅茨鼓風機、電機、空氣濾清器、進出口消音器、止回閥、安全閥、壓力表、減震器、軟性接頭、底座等部件于一體,結構緊湊、成套供應。該系列風機具有高效低噪,機組自我保護功能齊全,對管路系統和地基隔震功能好,同時具有羅茨鼓風機的通用特點:強制輸氣、輸送介質絕對不含油等特點。

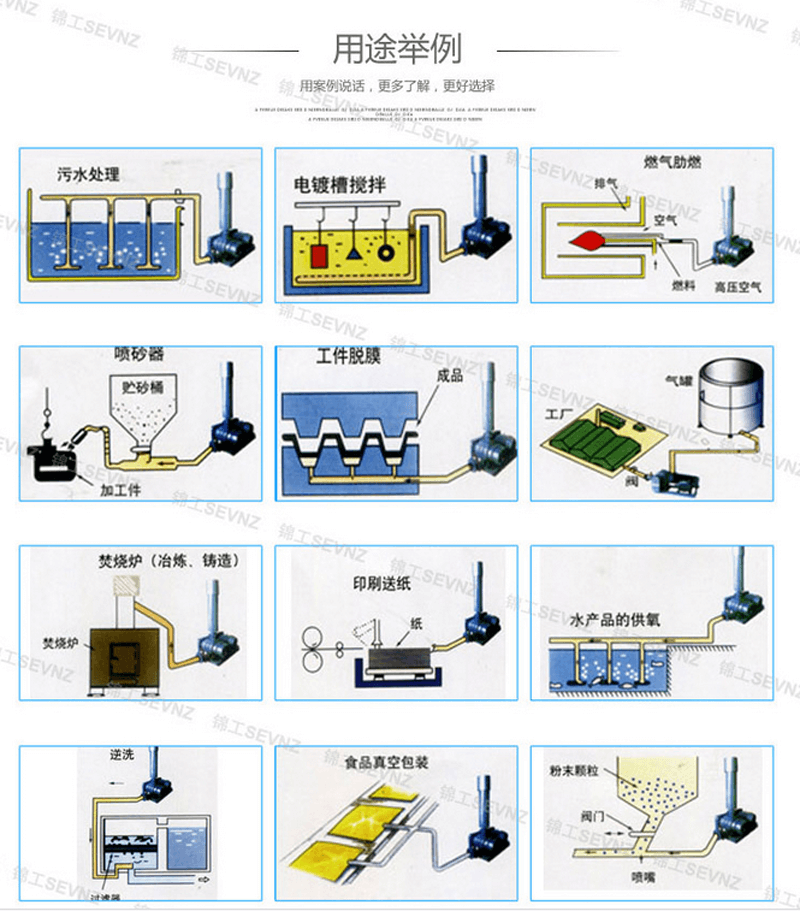

產品用途:

主要用于水泥、污水處理、水產養殖、冶煉、化工、電力等行業鼓風、氣力輸送等領域,輸送介質為空氣。

性能特點:

1、風機使用壓力29.4~78.4kpa,應用廣泛。

2、風機風量1.52-58.02m3/min覆蓋面大,應用范圍廣。

3、風機葉輪采用復合型線,嚙合完美,泄露少,效率高。

4、鼓風機材料是球墨鑄鐵,外形輪廓采用數控機床成型,齒輪5級精度,采用進口雙列軸承,轉子動平衡精度高于G6.3級,因此產品噪音低、運行可靠。

5、氣流脈動小,整機震動低,運行平穩,對風機安裝要求低。

6、產品整機結構緊湊,體積均勻,重量合理。

密集型羅茨鼓風機

JH錦工-50U:壓力:29.4~78.4kpa風量:1.52~2.59m3/min電機功率:1.5~5.5kw

JH錦工-65U:壓力:29.4~78.4kpa風量:2.14~3.51m3/min電機功率:2.2~7.5kw

JH錦工-80U:壓力:29.4~78.4kpa風量:3.65~5.88m3/min電機功率:4~15kw

JH錦工-100U:壓力:29.4~78.4kpa風量:5.18~9.81m3/min電機功率:5.5~18.5kw

JH錦工-125U:壓力:29.4~78.4kpa風量:6.56~12.85m3/min電機功率:7.5~30kw

JH錦工-150U:壓力:29.4~78.4kpa風量:10.75~29.13m3/min電機功率:15~75k

JH錦工-200U:壓力:29.4~78.4kpa風量:26.35~58.02m3/min電機功率:22~110kw

密集型羅茨鼓風機是根據普通三葉羅茨鼓風機衍生而來,密集型羅茨鼓風機的的選型與普通羅茨鼓風機的選型是一樣的,在選型、使用、維護方面和普通三葉羅茨鼓風機是一樣,但是密集型羅茨鼓風機有自己的特點:

1、體積小

2、占地面積小

3、對空間高度要求高

4、安裝更簡單

密集型羅茨鼓風機的主要適用的工況多為:地面空間有限,而垂直空間充足,此類工況下,可以很好的適用密集型羅茨鼓風機。

密集型羅茨鼓風機可以做成皮帶傳動,也可以做成直連傳動,可以根據用戶需求進行定制,密集型的羅茨鼓風機可以從50型號做到350型號,可以滿足我們的型號需求。

錦工風機專業生產密集型羅茨鼓風機,如果您有此方面的需求,可以聯系我們的官方客服熱線

:免費下載資料

國產老品牌:〖錦工〗?所有者錦工風機公司官網高壓風機升壓高達2.3MPa(2300KPa)

電話(Tel):86-0838- / 傳真(Fax):86-0838-

地址(Add):四川省廣漢市沱水路18號 郵碼(Zip): 郵箱(Email):

技術支持:錦工公司網辦 備案號:蜀ICP備號

關鍵詞:羅茨風機 羅茨鼓風機廠家 鼓風機 風機 磁懸浮鼓風機 燒結風機 多級離心鼓風機 鍋爐引風機 高壓風機 鍋爐引風機 雙級羅茨鼓風機 高速風機 四錦工風機

相關文章閱讀:

三葉羅茨鼓風機工作原理:

密集型羅茨鼓風機均為三葉羅茨鼓風機,羅茨風機為容積式風機,輸送的風量與轉數成比例,三葉型葉輪每轉動一次由 2 個葉輪進行 3 次吸、排氣。與二葉型相比,氣體脈動性小,振動也小,噪聲低。風機 2 根軸上的葉輪與橢圓形殼體內孔面,葉輪端面和風機前后端蓋之間及風機葉輪之間者始終保持微小的間隙,在同步齒輪的帶動下風從風機進風口沿殼體內壁輸送到排出的一側。風機內腔不需要潤滑油,結構簡單,運轉平穩,性能穩定,適應多種用途,已運用于廣泛的領域。

三葉羅茨鼓風機的特點:

● 由于采用了三葉轉子結構形式及合理的殼體內進出風口處的結構,所以風機振動小,噪聲低。

● 葉輪和軸為整體結構且葉輪無磨損,風機性能持久不變,可以長期連續運轉。

● 風機容積利用率大,容積效率高,且結構緊湊,安裝方式靈活多變。

● 軸承的選用較為合理,各軸承的使用壽命均勻,從而延長了風機的壽命!

● 風機油封選用進口氟橡膠材料,耐高溫,耐磨,使用壽命長。

● 機種齊全,可滿足不同用戶不同用途的需要。

● 采用線形優化后葉輪曲線和特殊結構的殼體,效率提高10%左右。

?主要技術指標:

●流量0.5m3~200m3/min;

●升壓:9.8~78.4kPa。

The three-lobe roots type rotary blower type JGR of is a new product which has been developed by adopting innovated techniques, based on the manufacturing experience in the roots type rotary blowersfor many years.

The three-lobe roots type JGR high pressure rotary blower is a new product which has been developed by adopting innovated techniques,based on the manufacturing experience in the roots type rotary blowers for many years.

These blowers have improved full-adiabatic efficiency as well as volumetric efficiency and provide supperior air capacity vs.pressure characteristic.

The superiority of efficiency leads to reduction of the heat from the blower itself,and therefore,reduction of the temperature elevation,and thus the operation of blower in dry condition has become practical at the discharge pressure as low as 0.8kgf/cm2.

Roots Type rotary Blowers Features

1 JGR-HB three-lobe blowers needn’t water coolant within 80kpa boost pressure.

2 the helical construction uses the stator helical method that the screen lines of casing at the suction and discharge sides are cut to a helical shape,and the triangle suction and discharge port formed by a straight line of the rotor top is to be opened and closed gradually.

Therefore,the suction and discharge ports of this type is not opened or closed at momnets,which makes these blowers have an only limited operation suound and almost free from pulsations from discharge.

3 The rotors are ghree-lobe straight type,so that the rotors cannot interfere with each other,resulting from minor displacements in the trust direction as in the helical type.Therefore,the clearance between the rotors should be assured in the profile direction only and thus there is no necessity of an excessive clearance on account of displacements in the thrust direction as in case of the rotor helical type.From such reasons,these blowers hav e a very high efficiency,in comparison with the rotor helical type of same dimensions.

4 By adoption of an unique profile of rotor,the clearance between the rotors can be held to be constant,which makes the efficiency even higher.

5 The precision of rotors if fully controlled and variation of precision between blowers is almost nil because the rotors are produced under the mass production control by utilizing a premision NC maching.In addition,the rotors are dynamically balanced in the faJGRication stage already,so that these rotors are almost free from viJGRations as in the case of conventional rotors which are still unbalanced.

6 The advancedest driving gears are adopted not only to extend the use life but also to make noise lower.The gears are made in special Cr-M.steel by hardening treatment and are made according with gear precision of JIS first-class.Therefore,the harmful disturbances to products from gears are avoided.

7 The transported air is clean and any oil-dust free oil luJGRication is not needed in casing and the structure design present the bearing oil and gear ooil from entering the casing.

8 With the establishment of quality management system and manufacture management system,the aims of parts exchanging,less production cost and rapid delivery are realized.The blowers of right quantity are keeped in stock to make delivery in time.

山東錦工有限公司

山東省章丘市經濟開發區

24小時銷售服務

山東錦工有限公司

地址:山東省章丘市經濟開發區

電話:0531-83825699

傳真:0531-83211205

24小時銷售服務電話:15066131928